Roads & Airports Products

A full range of standard bitumen grades are available to various international standards used in different countries:

Penetration grade bitumen complying with ASTM D946.

Additional Penetration grades complying with EN 12591 can also be sourced depending on project requirements

40/50 PEN I 50/70 PEN I 60/70 PEN I 80/100 PEN I 100/120 PEN I 120/150 PEN

Viscosity grade bitumen complying with ASTM D3381, AASHTO M226 and IS 73:2006

VG10 I VG20 I VG30 I VG40

Available for shipment in both Containerised and Bulk cargoes or by road in bulk 25-40 MT tanker, 20 MT bitutainer or 200L Drums.

Oxidised Grade Bitumen (115/15) complying with BS EN 13304:2009 for Industrial applications

A range of PG grade binders complying with AASHTO M320 are available, selection of which depends on climatic variation in different countries.

CYTECH has the expertise and know-how from many years of international supply using a variety of bitumen sources with different binder modifiers including polymers when appropriate to achieve the required properties.

For cooler climates e.g. New Zealand, Cyrus Infrastructure would supply PG 64-16 whereas for the Middle East region, PG 76-22 has typically been supplied.

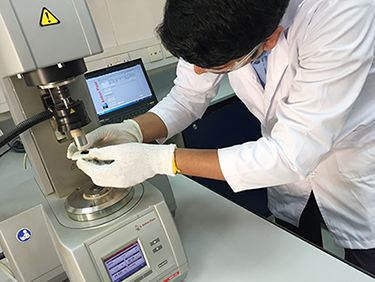

CYTECH International has unparalleled experience across the Middle East region complying to different specifications for PMB asphalt binders on major infrastructure projects with special focus on binder performance in the Middle East climate e.g. Abu Dhabi (PG 82-22) and Doha (PG 76-22 / PG 76-1 OE) International Airports. CYTECH can supply PMB to any of the following standard specifications:

AASHTO M320 using state-of-art hybrid polymer technology

AASHTO M332-14 using hybrid polymer technology to meet the full range of PMB asphalt binders graded by performance, using the multiple stress creep recovery (MSCR) test. Grading designations are related to the average seven-day maximum pavement design temperature, minimum pavement design temperature, and traffic loading. This specification incorporates T 350 for determining non-recoverable creep compliance, Jnr. "S," "H," "V," or "E" designations are specified for standard, high, very high, or extremely high traffic loading, respectively.

EN 14023 using elastomeric hybrid binders designed to suit climatic conditions and complying with the European Specification Framework for PMB.

SPECIAL 'PMB' grades which are bespoke polymer modified bitumen grades designed to meet project specific requirements.

All types of rapid to slow setting bitumen emulsion both anionic and cationic are manufactured in compliance with the following Standard Specifications:

ASTM D977-13 and AASHTO M140 for all ANIONIC Emulsified bitumen for pavement construction.

BS 434-1 :2011 Bitumen road emulsions Part 1 - Specification for ANIONIC bitumen road emulsions e.g. K1-40 and K1-60. (These grades are still specified for use on some contracts but please note this specification applies only to anionic emulsion. BS 434-2:2006 Specification for Cationic bitumen emulsions has been withdrawn and is replaced in Europe by BS EN 13808:2013 Framework for specifying Cationic bitumen emulsions).

ASTM D2397M-13 and AASHTO M208 for all CATIONIC Emulsified bitumen for pavement construction.

| ANIONIC GRADES | CATIONIC GRADES |

|---|---|

|

SS-1 |

CRS-1 |

|

SS-1h |

CRS-1h |

|

K1-40 |

CSS-1h |

|

K1-60 |

|

Available in 25MT Bulk road tanker, 1 MT IBC, 200L Drums.

Incorporating selected high quality solvents Cyrus Infrastructure manufactures all grades and types of Cutback bitumen to meet the requirement of different project specifications:

Medium Curing Cutbacks

Manufactured to comply with ASTM D2027M-13 and AASHTO M82 Standard Specifications for MediumCuring cutback petroleum bitumen in the construction and treatment of pavements

MC-30 I MC-70 I MC-250 I MC-800 I MC-3000

Rapid Curing Cutbacks

Manufactured to comply with ASTM D2028M-15 and AASHTO MB 1 Standard Specifications for RapidCuring cutback petroleum bitumen in the construction and treatment of pavements.

RC-70 I RC-250 I RC-800 I RC-3000

CYTECH International also offers specialist on-site technical expertise for customers requesting advice and guidance on Cutback selection and application rates.

Available in 25MT Bulk road tanker, 20MT Bitutainers, 200L Drums.

CYTECH produces a range of polymer modified bituminous repair materials for the purposes of sealing and rehabilitating cracked surfaces in asphalt and concrete pavement structures.

Suitable for various applications ranging from roads, airfields, ports to car parks and industrial areas.

CYTOPAVE RR

Polymer modified bituminous crack sealant for asphalt and concrete pavements using ‘rout and seal’ method. Sealant is a hot applied single component giving excellent adhesion to both asphalt and concrete substrates without the need for a primer.

CYTOPAVE RS

Polymer modified bituminous crack sealant for asphalt and concrete pavements using ‘recess’ method. Sealant is a hot applied repair compound containing fibre, rubber and granite aggregate.

CYTOSEAL F1

Fuel Resistant, hot applied elastomeric Pitch/PVC Sealant for Joints and Cracks in Portland Cement Concrete highway and airfield pavements. Complies with ASTM D7116-05 and formerly BS 2499:1993 Type F1 (now withdrawn)

CYTOSEAL N1

Hot applied elastomeric bituminous Joint Sealant for Concrete and Asphalt pavement joints particularly in airfield applications if no risk of fuel spillage. Complies with ASTM D6690-15 and formerly BS 2499:1993 Type N1 (now withdrawn)

CYTOSEAL LS

Polyester Loop Sealant for electric cable trenches in airfields and roads. Complies with ASTM D149-13 and BS 6319-2:1983 and BS 6319-3:1990